System Maintenance: 7 Ultimate Secrets for Peak Performance

Ever wondered why some systems run like clockwork while others crash at the worst time? The secret lies in smart, consistent system maintenance. It’s not just about fixing problems—it’s about preventing them before they happen.

What Is System Maintenance and Why It Matters

System maintenance is the backbone of operational efficiency across industries. Whether it’s a computer network, manufacturing line, or a cloud infrastructure, regular upkeep ensures longevity, reliability, and peak performance. Without it, even the most advanced systems degrade over time, leading to costly downtime and security vulnerabilities.

Defining System Maintenance

System maintenance refers to the routine activities performed to keep systems—hardware, software, or hybrid—functioning optimally. These activities include updates, repairs, diagnostics, and preventive checks. According to the International Organization for Standardization (ISO), effective maintenance is a strategic process, not a reactive fix.

- Ensures system reliability and availability

- Reduces the risk of unexpected failures

- Extends the lifespan of equipment and software

Types of System Maintenance

There are four primary types of system maintenance, each serving a unique purpose in the lifecycle of a system:

- Corrective Maintenance: Actions taken after a failure to restore functionality.

- Preventive Maintenance: Scheduled tasks to prevent breakdowns before they occur.

- Predictive Maintenance: Uses data and monitoring tools to predict when maintenance is needed.

- Perfective Maintenance: Enhancements to improve performance or usability.

“Maintenance is not a cost center—it’s an investment in reliability.” — Industry Expert, IEEE Transactions on Reliability

The Critical Role of System Maintenance in Business Operations

In today’s fast-paced digital economy, system maintenance is no longer optional—it’s a competitive necessity. Organizations that neglect it risk data loss, security breaches, and operational paralysis. A study by Gartner found that unplanned downtime costs enterprises an average of $5,600 per minute.

Minimizing Downtime and Maximizing Uptime

Downtime is the silent killer of productivity. System maintenance directly combats this by identifying potential issues before they escalate. For example, routine server patching can prevent a cyberattack that might otherwise take systems offline for days.

- Scheduled maintenance windows reduce disruption

- Automated monitoring tools alert teams to anomalies

- Redundant systems allow for seamless failover during maintenance

Cost Efficiency Through Proactive Maintenance

While maintenance requires upfront investment, it saves money in the long run. Reactive fixes are often more expensive due to emergency labor costs, data recovery, and lost revenue. Preventive system maintenance can reduce repair costs by up to 30%, according to research from McKinsey & Company.

- Reduces emergency repair expenses

- Lowers energy consumption through optimized performance

- Delays costly hardware replacements

System Maintenance in IT: Keeping Digital Infrastructure Running Smoothly

In the realm of information technology, system maintenance is vital for ensuring data integrity, security, and service continuity. From operating systems to cloud platforms, every digital asset requires regular attention.

Software Updates and Patch Management

One of the most critical aspects of IT system maintenance is keeping software up to date. Cybercriminals often exploit known vulnerabilities in outdated software. Regular patching closes these security gaps.

- Operating system updates (e.g., Windows, Linux, macOS)

- Application patches for CRM, ERP, and productivity tools

- Automated patch deployment using tools like WSUS or SCCM

Hardware Diagnostics and Server Maintenance

Even in cloud-centric environments, physical hardware still plays a role. Servers, routers, and storage devices need regular diagnostics to prevent hardware failure.

- Monitoring CPU, RAM, and disk usage

- Checking for overheating and power supply issues

- Replacing aging components before failure

“A server crash isn’t a matter of if, but when—unless you maintain it.” — IT Operations Manager, Fortune 500 Company

Preventive vs. Predictive Maintenance: What’s the Difference?

While both preventive and predictive maintenance aim to avoid system failure, their approaches differ significantly. Understanding the distinction helps organizations choose the right strategy.

Preventive Maintenance: The Scheduled Approach

Preventive maintenance follows a fixed schedule—weekly, monthly, or quarterly—regardless of the system’s current condition. It’s like changing your car’s oil every 3,000 miles, even if it seems fine.

- Based on time or usage intervals

- Easy to plan and budget for

- May lead to unnecessary maintenance if overdone

Predictive Maintenance: Data-Driven Intelligence

Predictive maintenance uses real-time data from sensors and analytics to determine when maintenance is actually needed. This approach is more efficient and cost-effective, especially in complex systems.

- Leverages IoT sensors and machine learning

- Monitors vibration, temperature, and performance metrics

- Reduces maintenance frequency without increasing risk

Best Practices for Effective System Maintenance

Successful system maintenance isn’t just about doing tasks—it’s about doing them right. Implementing best practices ensures consistency, accountability, and measurable results.

Create a Comprehensive Maintenance Plan

A well-documented maintenance plan outlines what needs to be done, when, and by whom. It should include checklists, schedules, and escalation procedures.

- Define maintenance goals and KPIs

- Assign responsibilities to team members

- Integrate with IT service management (ITSM) tools like ServiceNow

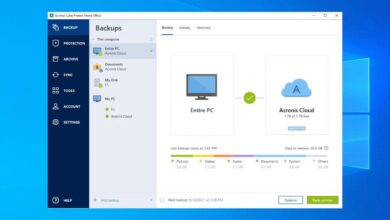

Use Automation Tools to Streamline Processes

Manual maintenance is error-prone and time-consuming. Automation tools can handle repetitive tasks like backups, updates, and log analysis with greater accuracy and speed.

- Script-based automation (e.g., PowerShell, Bash)

- AI-driven monitoring platforms (e.g., Datadog, Splunk)

- Scheduled tasks via cron jobs or Windows Task Scheduler

Document Everything for Accountability and Audits

Every maintenance activity should be logged. Documentation provides a historical record, aids in troubleshooting, and ensures compliance with regulatory standards like ISO 27001 or HIPAA.

- Record date, time, technician, and actions taken

- Store logs in a centralized, secure repository

- Use version control for configuration changes

Common Challenges in System Maintenance and How to Overcome Them

Even with the best intentions, organizations face obstacles in maintaining their systems effectively. Recognizing these challenges is the first step toward overcoming them.

Lack of Skilled Personnel

Many companies struggle to find technicians with the right expertise, especially in niche areas like cybersecurity or industrial automation. This gap can lead to poorly executed maintenance.

- Solution: Invest in training and certifications

- Partner with managed service providers (MSPs)

- Use remote monitoring and support tools

Budget Constraints

Maintenance is often seen as a cost rather than an investment, leading to underfunding. However, cutting corners now can result in much higher expenses later.

- Solution: Present ROI analysis to stakeholders

- Adopt phased implementation of predictive tools

- Leverage open-source monitoring solutions

Resistance to Change

Teams may resist new maintenance procedures, especially if they disrupt workflows. Cultural inertia can hinder the adoption of best practices.

- Solution: Involve staff in planning and decision-making

- Communicate the benefits clearly

- Start with pilot programs to demonstrate success

Future Trends in System Maintenance: AI, IoT, and Beyond

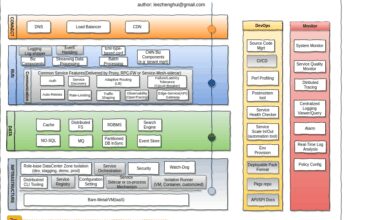

The landscape of system maintenance is evolving rapidly, driven by advancements in artificial intelligence, the Internet of Things (IoT), and cloud computing. These technologies are transforming maintenance from a manual task to a strategic, data-driven function.

AI-Powered Predictive Analytics

Artificial intelligence is revolutionizing system maintenance by analyzing vast amounts of data to predict failures with high accuracy. Machine learning models can detect patterns invisible to human operators.

- AI identifies anomalies in system behavior

- Reduces false alarms and improves response time

- Used in industries from aviation to healthcare

The Rise of IoT in Real-Time Monitoring

IoT devices are embedded in everything from factory machines to office HVAC systems. They continuously collect and transmit performance data, enabling real-time monitoring and instant alerts.

- Sensors track temperature, pressure, vibration, and more

- Data is sent to cloud platforms for analysis

- Enables remote diagnostics and maintenance

Cloud-Based Maintenance Management Systems

Cloud platforms are making it easier than ever to manage maintenance operations across multiple locations. These systems offer centralized dashboards, mobile access, and integration with other business tools.

- Examples include UpKeep, Fiix, and IBM Maximo

- Supports collaboration between teams

- Provides real-time reporting and analytics

System Maintenance Across Industries: Real-World Applications

System maintenance isn’t one-size-fits-all. Different industries have unique requirements based on their equipment, regulations, and operational demands.

Manufacturing: Keeping Production Lines Alive

In manufacturing, unplanned downtime can halt production and delay shipments. Preventive and predictive maintenance are critical for maintaining throughput and quality.

- Regular calibration of CNC machines

- Vibration analysis on motors and conveyors

- Integration with SCADA systems for real-time oversight

Healthcare: Ensuring Patient Safety and Data Security

Hospitals rely on a wide range of systems—from MRI machines to electronic health records (EHR). Maintenance ensures both equipment reliability and compliance with HIPAA.

- Daily checks on life-support systems

- Regular security audits for patient data

- Backup power system testing

Transportation: From Airplanes to Trains

Safety is paramount in transportation. Rigorous system maintenance schedules are enforced by regulatory bodies like the FAA and FRA to prevent accidents.

- Aircraft undergo A, B, C, and D checks at set intervals

- Trains are inspected for brake systems and track alignment

- Fleet management software tracks vehicle health

What is the main goal of system maintenance?

The main goal of system maintenance is to ensure that systems operate efficiently, reliably, and securely by preventing failures, extending lifespan, and minimizing downtime through regular updates, diagnostics, and repairs.

How often should system maintenance be performed?

The frequency depends on the system type and usage. Critical systems may require daily monitoring, while others follow weekly, monthly, or quarterly schedules. Predictive maintenance can optimize timing based on real-time data.

What are the benefits of predictive maintenance over preventive maintenance?

Predictive maintenance reduces unnecessary servicing by acting only when needed, saving time and resources. It uses real-time data to anticipate failures, leading to higher efficiency and lower costs compared to fixed-schedule preventive maintenance.

Can small businesses benefit from system maintenance?

Absolutely. Small businesses may have fewer resources, but they are equally vulnerable to system failures. Even basic maintenance routines—like regular backups and software updates—can prevent data loss and cyberattacks.

Is system maintenance only for IT systems?

No, system maintenance applies to any complex system, including mechanical, electrical, industrial, and hybrid environments. It’s essential in manufacturing, healthcare, transportation, and energy sectors, not just IT.

System maintenance is far more than a technical chore—it’s a strategic imperative. From preventing costly downtime to ensuring compliance and safety, its impact spans industries and functions. By embracing best practices, leveraging automation, and staying ahead of trends like AI and IoT, organizations can transform maintenance from a reactive burden into a proactive advantage. The future belongs to those who maintain not just their systems, but their competitive edge.

Further Reading: